My storage ideas came from Steve Ramsey of Woodworking for Mere Mortals on YouTube (https://www.youtube.com/watch?v=nZtIEFa3Ofk&index=4&list=PL2Y7G15DrVt7tgzyaDbciZ-rm6tmToHoF), Marc Spagnuolo of The Wood Whisperer on YouTube (https://www.youtube.com/watch?v=NSUwyMdPAEg) by way of April Wilkerson's blog (http://wilkerdos.blogspot.com/2014/06/diy-wall-lumber-rack.html#more) and YouTube video (https://www.youtube.com/watch?v=ZmZMyqbDSDY).

Jay Bates has a nice video on a Sketch Up design for a wall rack just like the one one I built below as well as a design modification using conduit pipe for the supports.

Sketch Up video http://youtu.be/T6EdflepU2E

Modification video http://youtu.be/_V4MJyrAG9w

So, while the rest of you were watching the Super Bowl, this is what I was doing. Steve made a comment that you really do not need storage for 4x8 sheet goods. If you need a sheet for a project, go out and get it just before you need it. However, you may end up with 8 foot scraps......that's part of the reason why I also built a wall rack. If I have 8 foot pieces in this rack, I can not get the rack under the "Man Loft" (that's another post in the future) or the garage door.

When you get to this stage of the build, it is a real good idea to pre-drill holes for screws from the dado side. It makes it a lot easier to place the screws later. I now do this with all my projects that have dadoes.

Heavy duty casters are a must - wood gets heavy.

I have found this to be very useful - Thanks Steve for sharing this.

I used my Festool track saw to cut the strips.

I used my Paulk Cross Cut Jig to cut the strips to 18 inch lengths.

To make the angle cut along the bottom of the support, I had to make a quick jig. Scrap wood and a pin nailer came in handy. I could not use the miter gauge with my table saw like April did as my supports are 18 inches and thus to long to use the miter gauge. April's supports are 12 inches and Marc's are 21 1/2 inches. Mine were limited to the space between the wall and the garage door track.

There is an angled cut on the right side - the line goes from a mark 3 1/2 inches from the top left corner to a mark 3 1/2 inches up from the bottom right corner. I had to make 24 of these cuts for my rack. Here's the jig I made which made making these cuts a breeze. It's not pretty but it worked great.

The piece of wood sits at an angle with the cut line along the edge of the base of the jig.

The track sits on top and the right hand edge is even with the edge of the jig. The section of the wood to be cut off extends to the right.

The 2x4s were cut to 14 3/4 inches in length. To make the support sandwiches.

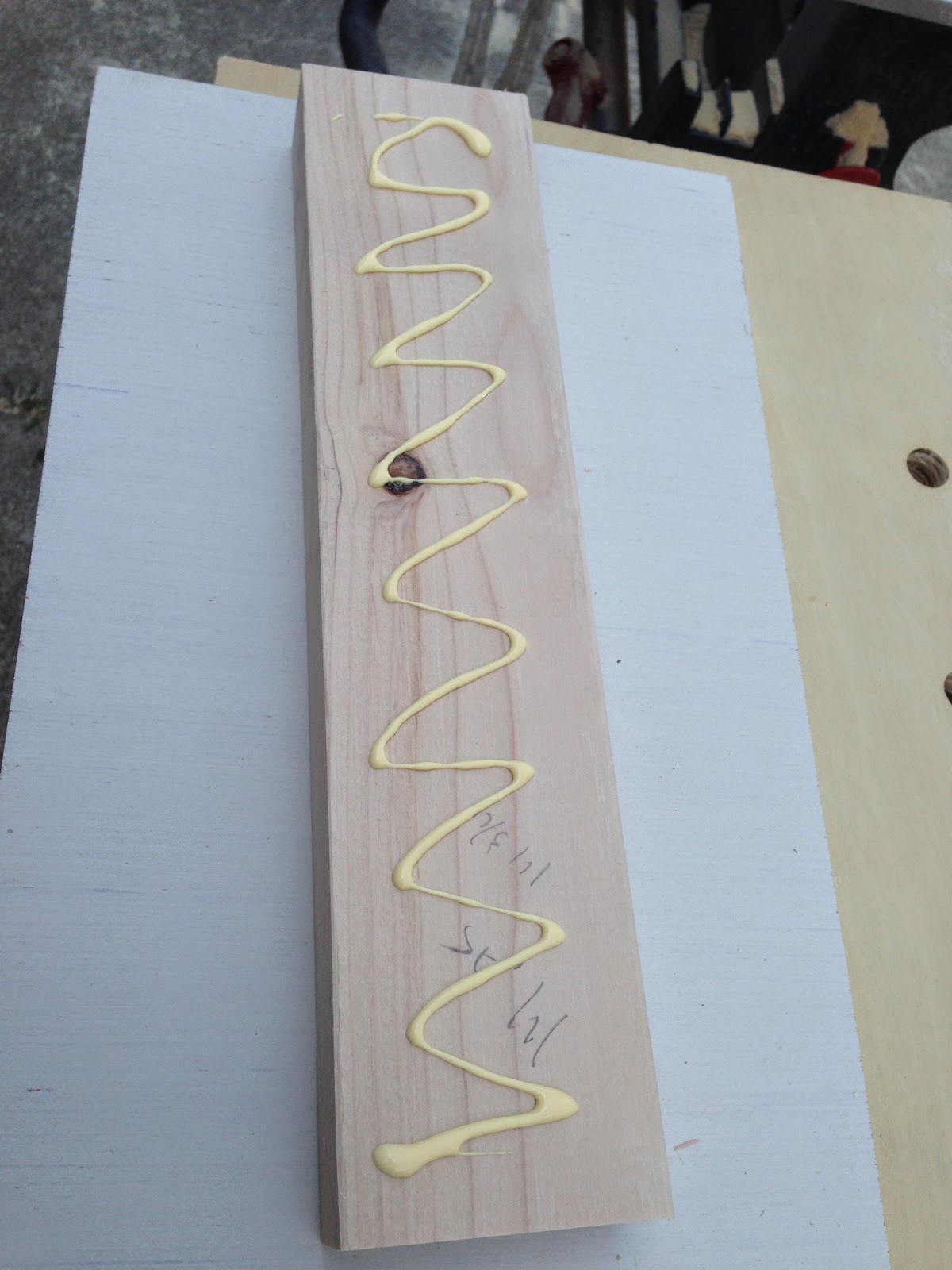

A plastic scraper is useful for spreading the glue.

I used a pin nailer to secure the plywood to the 2x4 and the used 3 stainless screws on each side for more permanent fixation. I recommend stainless screws be used since they have a much great resistance to shear force compared to dry wall screws

I trimmed my vertical supports to 3 1/4 inches wide like April did in her blog/video and recommend you do this as well. It makes for a nice flat surface on the top side of the support and makes it easier to align the plywood with the top edge of the 2x4. Attaching the vertical supports can be a bit of a challenge. I did not have an impact driver so I used my socket wrench - ended up with a sore shoulder. I used 4 inch lag bolts. I first drilled a hole just larger than the washer using a spade but. I then drilled the pilot hole just larger than the diameter of the lag screw. You must do this in order for the lag screw to work properly. It should not engage the 2x4 if it is going to pull it into the wall as you screw it into the stud. You want the lag screw to screw at least an inch into the stud. You need to consider the thickness of the wall covering (sheet rock etc) in determining the depth of the hole you drill in the vertical support in order to get good purchase into the stud. I used a ledger board like Marc did. This made attaching the vertical support much easier.

Having a long level makes attaching the wood support pieces level to each other much easier.

A short level helps with making sure the supports are level

Marc mentions that the supports should not be more than 48 inches apart or you'll have sagging issues. I had no choice due to where I located my rack. I solved the problem by using pocket screws to attach 2x4s between the supports.

I have 4 levels here just under 8 feet in length

Loaded up with all my long pieces of wood - now I can get my mobile rack under the garage door if I need to. The top rack is loaded with about 12 inches of wood above the garage door track. I store my Paulk Cross Cut Jig on the lower section for now - out of the way with easy access

Between Steve's mobile storage bin and Marc's wall rack, you should have plenty of storage. I recommend you watch both Marc and April's videos as well as read April's blog post.

Hope this helps.

Looks a good project. I might have to build something like this when I get my new workshop set up!

ReplyDeleteKev, it's simple ans easy to do. I'd recommend following the links to Marc's video as well as April's blog and video to get more information on building the rack. The mobile cart is also quite handy but will take more time to build

Delete